At Advanses, we specialise in material testing and finite element analysis (FEA) services for elastomeric components used in automotive, defence, aerospace, medical and industrial applications. One of the most critical design challenges our clients face is accurately predicting the fatigue life of rubber parts operating under complex, real-world loading environments.

In this article, we explore why fatigue life prediction of rubber components is widely considered difficult, and how modern critical plane analysis methods, particularly those based on cracking energy density (CED), offer a powerful and proven approach for accurate fatigue simulation and design optimisation.

Why Fatigue Life Prediction of Rubber Is Difficult

Rubber exhibits highly nonlinear, strain-dependent behaviour and undergoes large deformations that challenge traditional stress- or strain-based fatigue models used for metals. In practice, most rubber components are subjected to multiaxial loading (e.g., compression + shear + torsion), which means that fatigue initiation does not occur on a single predetermined plane but depends on the combination of local stress/strain components.

Other complicating factors include:

- Strain-induced crystallisation (e.g., in natural rubber), which alters fatigue resistance

- Temperature and frequency effects, which influence fatigue damage rate

- Localized crack initiation, which may occur far from global stress concentration zones

These factors make simplified fatigue prediction approaches unreliable, especially when precision is required for regulatory approval or warranty confidence.

Critical Plane Analysis: A Better Approach for Elastomers

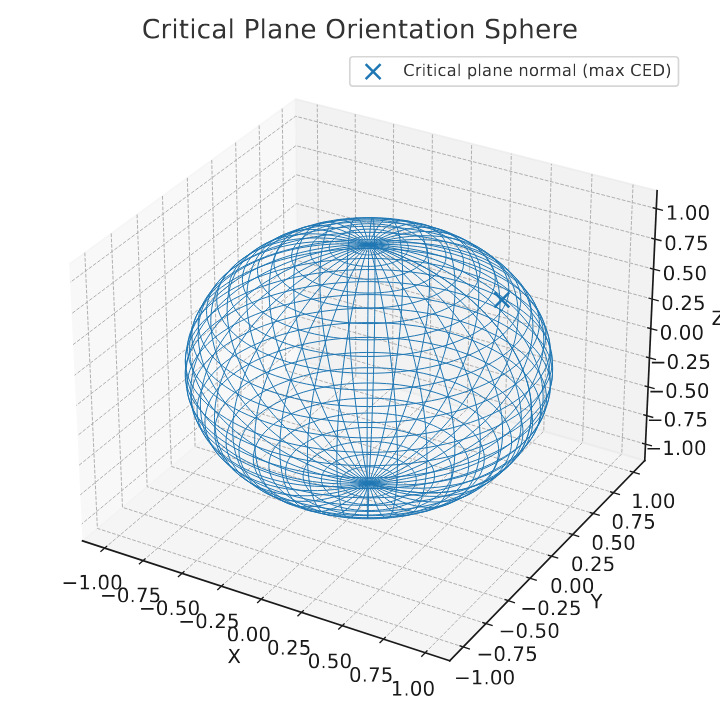

Critical plane analysis has emerged as a best-practice method for multiaxial fatigue assessment of rubber materials. Instead of relying on a global scalar value (e.g., von Mises strain), this method evaluates the fatigue parameters on all possible material planes and identifies the plane that is most susceptible to damage under the applied loading history.

Why it works so well for rubber parts:

| Conventional Approach | Critical Plane Approach |

|---|---|

| Uses a single scalar equivalent stress/strain | Evaluates stresses and strains on actual material planes |

| Often ignores shear-dominated damage | Captures both shear and normal components |

| Prone to inaccurate life prediction under multiaxial loading | Delivers physically-consistent fatigue life estimation |

At Advanses, we routinely apply critical plane-based fatigue analysis in our FEA projects, enabling our customers to identify where and on which plane cracks are most likely to initiate under real-world service conditions.

Cracking Energy Density (CED): A Physically-Based Fatigue Parameter

In order to quantify and accumulate damage on each plane, a fatigue damage parameter is required. While stress or strain-based amplitudes can be used, we strongly recommend Cracking Energy Density (CED) for elastomeric materials.

CED represents the amount of stored energy available to drive crack initiation and growth at a given point in the component. Because rubber fatigue is fundamentally driven by energy dissipation, CED exhibits excellent correlation with laboratory fatigue test results.

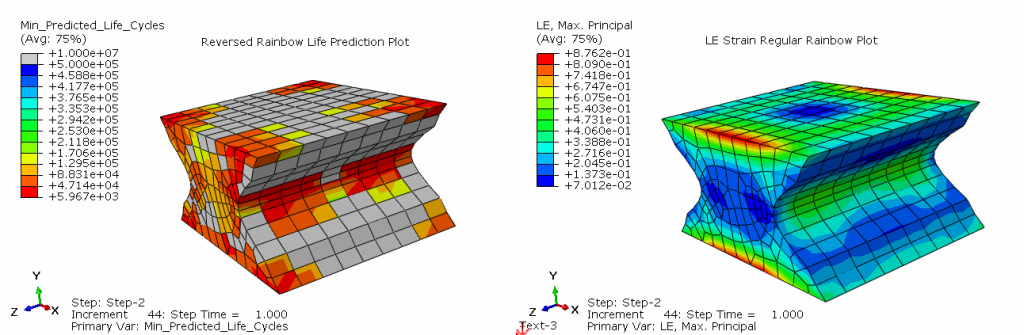

Plots showing the distribution of logarithmic strain in the part on the right hand side and the life prediction at the elemental level in the component. Reversed rainbow plotting for better visualization of results. Grey colors show infinite life and red colors show minimum life cycles.

Advantages of using CED in fatigue prediction:

- Fully compatible with nonlinear material behaviour

- Naturally accounts for tension-shear interaction (mode mixity)

- Consistent with continuum damage mechanics

- Directly applicable within a critical plane framework

By combining multi-axial loading histories (from FEA) with CED-based critical plane methods, Advanses can provide highly accurate, physics-based fatigue life prediction that matches experimental trends and helps our customers optimize geometry, material grade, and service limits.

Summary

Predicting the fatigue life of rubber components is far more complex than applying simple stress-life or strain-life models. By embracing critical plane analysis and cracking energy density-based damage parameters, engineers gain a powerful and practical toolset for making reliable life predictions, even under non-proportional and multiaxial loading.

At Advanses, we combine laboratory material testing capabilities with advanced finite element analysis to provide accurate and validated fatigue assessments for real components. Whether you require material data, fatigue test programs, or full FEA-based fatigue life prediction, our team can help you evaluate and optimise the durability of your elastomeric parts.

Contact us today if you would like to discuss your rubber fatigue analysis requirements.