In today’s competitive manufacturing landscape, plastic material testing has become more critical than ever. Whether you’re developing automotive components, medical devices, or consumer products, understanding the mechanical properties and performance characteristics of your plastic materials can make the difference between product success and costly failures.

Why Professional Plastic Testing Matters for Your Business

Plastic materials are ubiquitous in modern manufacturing, but their performance varies dramatically based on composition, processing conditions, and environmental factors. Professional plastic testing services provide manufacturers with essential data to:

Ensure Product Safety and Reliability

Without proper testing, plastic components can fail unexpectedly, leading to safety hazards, product recalls, and damaged brand reputation. NABL ISO/IEC 17025 accredited testing laboratories like AdvanSES provide reliable, internationally recognized test results that give manufacturers confidence in their product designs.

Meet Regulatory Compliance Requirements

Industries such as automotive, aerospace, and medical devices have stringent regulatory requirements for material properties. Professional testing ensures your products meet industry standards including ASTM, ISO, and sector-specific regulations.

Optimize Material Selection and Cost Efficiency

Understanding the precise mechanical properties of different plastic formulations helps engineers select the most cost-effective materials that meet

performance requirements without over-engineering.

Comprehensive Plastic Testing Services: What to Look For

When selecting a plastic testing laboratory, consider facilities that offer comprehensive testing capabilities:

Mechanical Property Testing

- Tensile Testing: Determines ultimate tensile strength, yield strength, and elongation properties

- Flexural Testing: Measures bending strength and modulus

- Impact Testing: Evaluates material toughness and energy absorption

- Compression Testing: Assesses load-bearing capabilities

- Hardness Testing: Determines surface resistance to indentation

Advanced Material Characterization

Modern plastic testing goes beyond basic mechanical properties. Look for laboratories offering:

- Hyperelastic Material Testing: Essential for rubber-like materials and elastomers

- Fatigue Testing: Critical for components subjected to cyclic loading

- Creep and Stress Relaxation Testing: Important for long-term performance prediction

- Environmental Stress Testing: Evaluates performance under various temperature and humidity conditions

Specialized Testing for Complex Applications

Composite Material Testing

As manufacturers increasingly adopt fiber-reinforced plastics, specialized composite material testing becomes essential. This includes:

- Fiber-matrix adhesion testing

- Interlaminar shear strength

- Mode I and Mode II fracture toughness

- Compression-after-impact testing

Polymer Aging and Durability Studies

Understanding how plastic materials degrade over time is crucial for product longevity. Accelerated aging studies help predict:

- UV degradation resistance

- Thermal aging effects

- Chemical compatibility

- Long-term mechanical property retention

The Value of NABL ISO/IEC 17025 Accreditation

When choosing a plastic testing partner, accreditation matters. NABL ISO/IEC 17025 accredited laboratories provide:

Global Recognition and Acceptance

Test reports from accredited laboratories are recognized internationally, facilitating global trade and regulatory acceptance.

Quality Assurance

Accreditation ensures laboratories maintain rigorous quality management systems, calibrated equipment, and competent personnel.

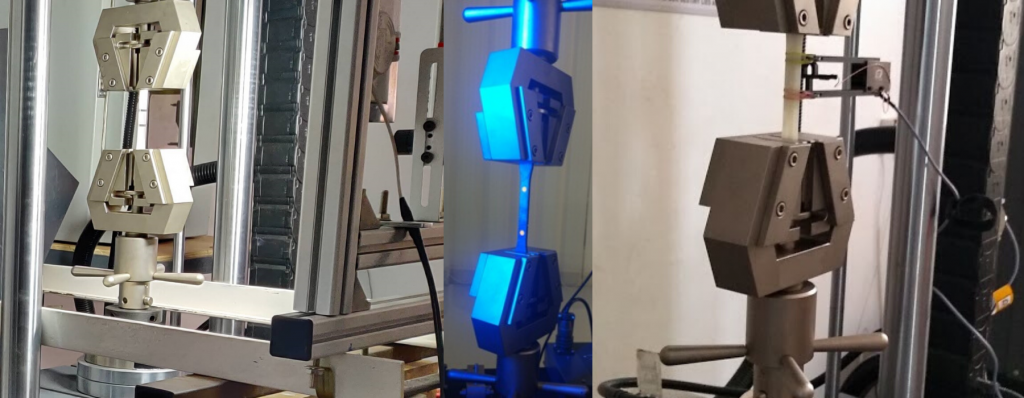

Advanced Testing Technologies and Equipment

Modern plastic testing laboratories utilize sophisticated equipment:

Getting Started with Professional Plastic Testing

Implementing a comprehensive plastic testing program involves:

- Assessment of Testing Needs: Identify critical material properties for your application

- Standard Selection: Choose appropriate testing standards (ASTM, ISO, industry-specific)

- Laboratory Partnership: Select an accredited testing laboratory with relevant expertise

- Test Plan Development: Create comprehensive testing protocols

- Results Implementation: Use test data for design optimization and quality control

Conclusion: Investing in Quality Through Professional Testing

Professional plastic testing is not just a regulatory requirement—it’s a strategic investment in product quality, safety, and market success. By partnering with an experienced, accredited testing laboratory, manufacturers can:

- Reduce product development risks

- Ensure regulatory compliance

- Optimize material usage and costs

- Build customer confidence

- Accelerate time-to-market

The complexity of modern plastic materials and applications demands sophisticated testing capabilities. Whether you’re developing next-generation automotive components, life-saving medical devices, or innovative consumer products, professional plastic testing provides the foundation for engineering excellence.

Ready to Enhance Your Product Quality?

If you’re looking for reliable, professional plastic testing services, consider partnering with an experienced NABL ISO/IEC 17025 accredited laboratory. With comprehensive testing capabilities, advanced equipment, and decades of experience, the right testing partner can help you achieve your quality and performance objectives.

Contact AdvanSES today to discuss your plastic testing requirements and discover how professional material characterization can enhance your product development process. Our team of experienced engineers and testing specialists is ready to provide the technical expertise and quality assurance your projects demand.

AdvanSES is an NABL ISO/IEC 17025 Accredited Independent Testing Laboratory with over 18 years of experience in material testing, failure analysis, and FEA consulting services. We serve clients across automotive, aerospace, medical device, and consumer product industries with state-of-the-art testing equipment and comprehensive technical support.