Today in industry Fatigue Life Prediction of Rubber Components Using Critical Plane Analysis is a challenge faced by engineers across automotive, aerospace, medical, and industrial sectors. Elastomeric components like seals, mounts, and bushings operate under complex, multiaxial loads that make traditional stress- or strain-based fatigue methods unreliable.

At Advanses, we specialize in combining experimental material testing and finite element analysis (FEA) to provide accurate fatigue life predictions. In this article, we explain how critical plane methodology, tearing energy experiments, and the cracking energy density (CED) theory come together to enable reliable fatigue life assessments for rubber materials.

1. Critical Plane Methodology

Unlike metals, where equivalent stress or strain criteria can often be used, rubber fatigue is highly dependent on the orientation of crack initiation.

Critical plane analysis solves this by evaluating fatigue parameters on all possible material planes and identifying the one most prone to crack initiation. Instead of using a single scalar (like von Mises stress), this method checks the local strain energy and shear/normal contributions on every plane.

🔑 Why it matters for rubber:

- Captures multiaxial load effects accurately

- Identifies where cracks will start (location + orientation)

- Aligns with physical fracture processes observed in elastomers

This approach is widely adopted in advanced FEA-based fatigue solvers and is a cornerstone of our fatigue services at Advanses.

2. Experimental Testing for Tearing Energy

While simulations are powerful, they must be anchored in experimental data. Rubber fatigue is fundamentally governed by the energy available to grow a crack, known as tearing energy (T).

In the lab, tearing energy is characterized through controlled crack growth tests:

- Specimens with a predefined notch are subjected to cyclic loading.

- The crack growth rate (dc/dN) is measured against tearing energy.

- The resulting dc/dN vs T curve becomes the material’s fingerprint for fatigue performance.

This curve is then fed into fatigue models, ensuring that life predictions are grounded in real-world fracture mechanics. At Advanses, we conduct such tests to supply our FEA models with reliable, material-specific fatigue data.

3. Theory and Application of Cracking Energy Density (CED)

Among various fatigue parameters, Cracking Energy Density (CED) has proven most effective for rubber.

CED represents the strain energy density available on a potential crack plane, combining both normal and shear contributions. Its advantages:

- Directly linked to crack initiation and growth mechanisms

- Works seamlessly with critical plane analysis

- Captures nonlinear, large-strain behavior typical of elastomers

- Correlates strongly with experimental crack growth data

In practice, CED is calculated for each orientation plane during simulation. The critical plane with the highest damaging CED determines the predicted fatigue life.

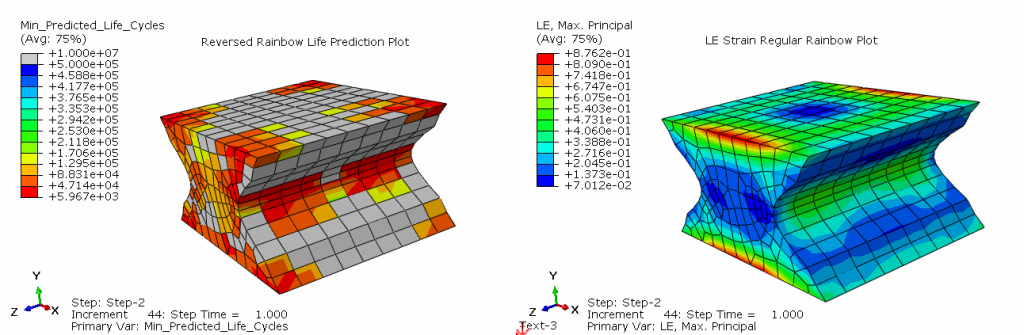

4. Fatigue Life Prediction

By integrating critical plane analysis, experimental tearing energy data, and CED-based models, fatigue life prediction of rubber components becomes accurate and practical.

At Advanses, our workflow typically includes:

- Material testing to establish dc/dN vs T curves.

- FEA simulations with critical plane + CED calculations across loading histories.

- Life prediction at each potential crack site, identifying the orientation and location of minimum fatigue life.

This combination ensures that predictions reflect both physics of crack growth and real-world performance, giving engineers confidence in design durability and product reliability.

Conclusion

Rubber fatigue analysis is complex — but with the right methodology, it becomes predictable.

- Critical plane analysis identifies the true crack initiation plane.

- Tearing energy experiments provide the experimental backbone.

- Cracking energy density bridges theory with application.

- Integrated FEA fatigue life prediction delivers actionable insights for design and testing.

At Advanses, we provide end-to-end fatigue testing and FEA services: from material testing to advanced simulations, ensuring your rubber components meet performance and reliability targets.

👉 Contact us today to discuss how we can support your fatigue analysis needs.