Finite Element Analysis (FEA) is a powerful tool used in engineering to simulate the behavior of structures and materials under different conditions. However, the accuracy of FEA results depends on the accuracy of the input parameters and assumptions made during the simulation. Strain gauging is a technique used to verify the accuracy of FEA results by measuring the actual strains in a structure and comparing them with the predicted strains from the FEA model.

What is Strain Gauging?

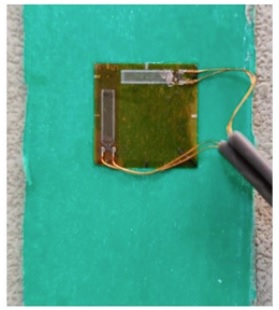

Strain gauging is a technique used to measure the strain in a material or structure. A strain gauge is a device that changes its electrical resistance when subjected to strain. The change in resistance is proportional to the strain, and this relationship is used to calculate the strain in the material. Strain gauges are attached to the surface of the material using a special adhesive, and the electrical resistance is measured.

There are several types of strain gauges used for different applications. Some of the common types include:

Linear Strain Gauges: These have one measuring grid and measure the strain in one direction. They are suitable when only one direction of strain needs to be investigated.

Quarter-Bridge, Half-Bridge, and Full-Bridge Configurations: These are determined by the number of active elements in the Wheatstone bridge and the type of strain being measured. Quarter-bridge, half-bridge, and full-bridge strain gauges are used to measure bending and axial strain, and they have different sensitivities and applications.

Rosette Strain Gauges: These include membrane rosette, tee rosette, rectangular rosette, and delta rosette. They are used to measure strain in multiple directions and are suitable for complex stress analysis.

Shear Strain Gauges, Column Strain Gauges, and 45°/90°-Rosette: These are used for specific applications where the strain needs to be measured in a particular direction or orientation.

Each type of strain gauge has its own characteristics, advantages, and applications. The selection of the appropriate strain gauge depends on the specific measurement task and the type of strain to be measured.

How is Strain Gauging Used for Verification of FEA?

Strain gauging is used to verify the accuracy of FEA results by measuring the actual strains in a structure and comparing them with the predicted strains from the FEA model. The process involves the following steps:

- Design and fabricate the structure to be tested.

- Install strain gauges at critical locations on the structure.

- Apply a known load or deformation to the structure.

- Measure the strains using the strain gauges.

- Compare the measured strains with the predicted strains from the FEA model.

- Adjust the FEA model parameters and assumptions to improve the accuracy of the predictions.

Benefits of Strain Gauging for Verification of FEA

Strain gauging is a valuable technique for verifying the accuracy of FEA results. Some of the benefits of strain gauging include:

- Provides a quantitative measure of the accuracy of FEA results.

- Helps identify errors in the FEA model parameters and assumptions.

- Improves confidence in the FEA results and reduces the risk of failure in the actual structure.

- Can be used to optimize the design of the structure by identifying areas of high stress or strain.

Conclusion

Strain gauging is a valuable technique for verifying the accuracy of FEA results. It provides a quantitative measure of the accuracy of the FEA model and helps identify errors in the model parameters and assumptions. By using strain gauging to verify FEA results, engineers can improve confidence in the design of structures and reduce the risk of failure.

References:

Helm JD, Sutton MA, McNeill SR. Deformations in wide, center-notched, thin panels, part II: finite element analysis and comparison to experimental measurements. Opt Eng 2003; 42(5): 1306–1320.

Hertelé S, de Waele W, Denys R, Verstraete M. Investigation of strain measurements in (curved) wide plate specimens using digital image correlation and finite element analysis. The Journal of Strain Analysis for Engineering Design. 2012;47(5):276-288.

Kartik Srinivas, Verifications and Validations in Finite Element Analysis, https://www.researchgate.net/publication/341727057_Verifications_and_Validations_in_Finite_Element_Analysis_FEA